Velox Plus

Why Velox Plus

We think on all points of difference Velox Plus is a superior choice, have a look at the notes below and the FAQ.

Don't live you with you head in the sand, barnacles et cetera on your props and running gear will make a DRAMATIC difference to both

- Fuel bill

- Top Speed

Depending on the extent of the marine intrusion, we have seen >25% degrade in performance and >25% increase in fuel consumption.

💡 An investment in Velox Plus will be a cash flow positive one after a few outings.

Velox Plus increases your fuel economy by preventing marine growth on your propellers, drives and submerged metal to reduce drag.

At RRP, typically Velox Plus is half the price of leading competitors.

As well as being competitively priced, Velox Plus has a 48-month shelf life, allowing you to save any remaining product for use at a later time.

Fishermen from Greece to Geraldton use Velox Plus, proof that it’s value for money!

In most years you don't need to go back to bare metal. This is a huge time saver.

Year 1

- Boating Products 2-part Etch Primer is needed

- on transition away from a silicon-based anti-foul * or

- you are unsure how to mechanically key a surface **

- Apply one coat of Metal Primer

- Apply three coats of Velox Plus

Subsequently ***

- Pressure wash with fresh water and/or sand very lightly with fine paper or abrasive felt. Leave to dry well.

- Touch up with Metal Primer as needed. Etch Primer not required.

- Apply three coats of Velox Plus

* to mitigate the risk of substrate contamination

** a mechanical key is required for the primer to bond with the substrate this means the surface is not smooth but has a sandpaper type texture (a series of peaks and valleys) which allows the primer to adhere easily to the surface profile.

*** every few (3-5) years reset back to bare metal and reapply (where relevant) Etch Primer and Metal Primer

Velox Plus can be brushed, rolled or spray-applied.

No need to rush due to Metal Primer & Velox Plus not having any catalyst added, allowing for quality application.

Work in tandem with other anti-foul/paint jobs, because it doesn’t contain silicon you need not worry about blotching.

For those used to silicon-base anti-foul you will need to change your paint programme back to a more traditional one. A typical programme (where you are purely hauling out for anti-fouling) might be;

- Day 1

- Strip hull & metals

- Finish the day with a thin layer of Etch Primer (noting metal will oxide beyond 6 hours typically) and then 30 minutes later (but no more than 5 hours) a coat of Metal Primer

- Day 2

- 3 coats of Velox Plus, noting at 30 degrees you need 2 hours b/n coats (3 hours at 20 degrees)

- Day 3

- Anti-foul your hull, noting Velox Plus can accommodate some over-spray

- Day 4

- Slip her back into the water

Where you have time you should do a coat a day of Metal Primer &/or Velox Plus.

If Velox Plus is scratched or damaged it will not all peel off, unlike “release” coatings or membrane-forming silicon-based products. This means you can dive and wipe/clean whenever you wish, typically after you've gotten the anchor down but before you have that beer or start work on dinner.

If you drag a line across Velox Plus - for example a rudder blade - it will be considerably more resilient and robust to damage as opposed to an ablative or especially a silicon membrane.

Galvanic and electrolytic corrosion is the most common cause of paint failure on metal below the water line. Marlin Yacht Paint’s Metal Primer and Velox Plus are built specifically to withstand degradation from galvanic currents.

Marlin Yacht Paints has very recently released an improved version of its Metal Primer with greater adhesion even in the presence of strong galvanic currents.

Thanks to an important research and development project carried out in collaboration with universities and research laboratories, critical problems were discovered due to which Metal Primer could suffer detachments in the presence of strong galvanic currents, for example in the event that the boat remains connected to electricity outlet for extended periods. This problem has been overcome thanks to innovative adhesion promoters and galvanic current inhibitors, so since season 2024 Metal Primer has significantly better adhesion.

Velox Plus is the most appreciated product of the entire Marlin Paints range and is currently exported all over the world, from America to Australia, from Europe to the Far East. Tens of thousands of boats successfully use Velox Plus, a rapidly growing number both in Italy and abroad thanks to the excellent results obtained, the growing demand and the expansion of the distribution network.

Produced for 30+ years and now applied to 100,000+ vessels per year globally. Locally, it's been used for the last 10+ years in Western Australia, from the brackish conditions of the Swan River to the salty Indian Ocean, from recreational boaties to cray fishermen.

Velox Plus is effective on ALL underwater metal components, including trim tabs, hangers, rudders, shafts and beyond.

Specifically take note this includes mainly components not typically able to be covered by silicon-based anti-foul.

Silicon is in the media at the moment. It has two chances to get into lungs; in the solvent on application or as dust particles on removal. Two impacts;

- potential health concerns, and

- financial exposure to potential litigation from your workforce, neighbouring businesses or customers.

Additionally, Silicon can get airborne as it's solvent evaporates. This can lead to blotching on nearby jobs. Especially relevant for applicators and slipways.

The Velox Plus system does not contain silicon, and thus will not blotch other paint jobs in-flight.

How does this play out? Typically where you are using a silicon-based anti-foul it needs to be done last, so it doesn't blotch or foul your other jobs. In addition, you need to put up a screen to stop silicon getting across the boatyard. This then increases a risk of delay because you can't shuffle things around when you invariably need to.

By using Velox Plus you give your painting schedule more flexibility and resilience during the hull & metals anti-foul process.

The Benefits of Velox Plus

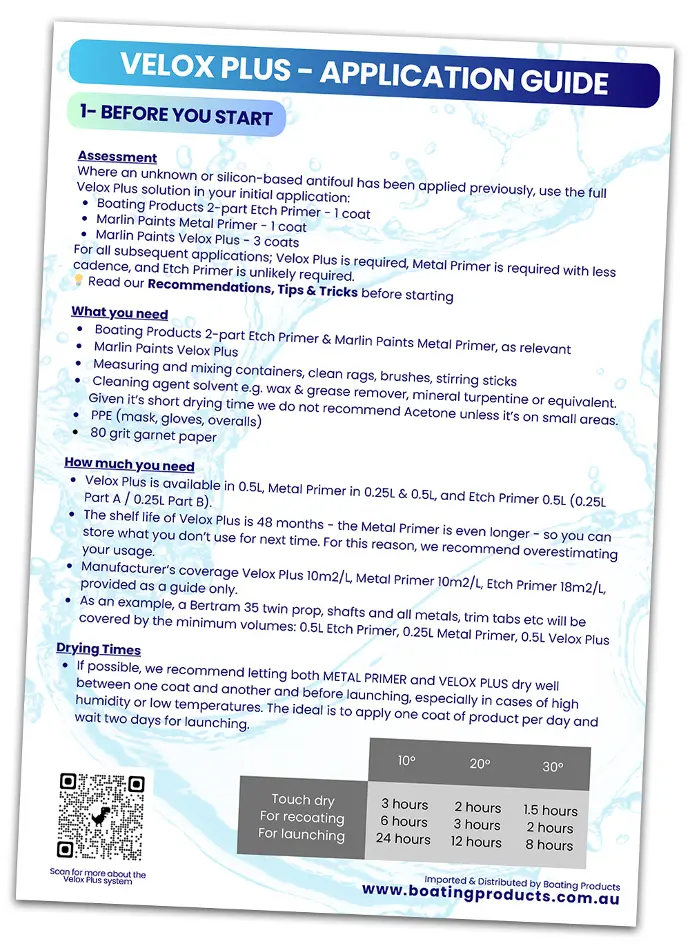

Coverage Chart

Guide only. Remember that even once opened you can lid these products for years, so if in doubt there’s no downside in over-estimating. click here for PDF

Application Guide

including Assessment, Preparation, Coverage, Recommendations, Tips & Tricks click here for PDF

FAQ Velox Plus

If you have any questions get in touch info@boatingproducts.com.au.

Velox Plus is a hard vinyl-based anti-foul. Unlike an ablative it is not designed to crumble. It has excellent adhesion qualities, specifically with the Metal Primer Marlin has very recently released an improved version with greater adhesion even in the presence of strong galvanic currents. Where a silicon-based anti-foul has already been used * we strongly recommend utilising our Etch Primer to mitigate any silicon contamination of the substrate.

The Etch Primer will go a long way. We recommend you start with 100ml of Part A & 100ml or Part B. Always mix by volume.

* OR you are not sure how to correctly mechanically key a surface

You should get 1-3 years of service from the Velox Plus system. There are many factors that will impact the success of your application. Preparation of the surfaces is the key. Please pay attention to electric discharge; from your vessel, nearby vessels and shore power. We recommend you utilise a galvanic isolator where you are hooked up to shore power. Where you are running solar, wind or other power generation on your vessel be mindful of electrical discharge, especially above 0.4V. You should regularly use your vessel, defined as 1-2 times per week. If this is not possible, then we recommend a regular visual inspection with a cloth to wipe clear any build up. Brackish, warmer, more stagnant water will require more attention.

Keep what you don't use for next time.

Boating Products Etch Primer can be stored for up to 24 months.

Marlin Yacht Paint's Metal Primer and Velox Plus can both be stored for up to 48 months once opened.

💡 Top Tip > make sure the paint lid is properly pushed down into place to create an airtight seal. Wiping any wet paint from the inside rim of the lid and the top of the can with a damp cloth will help to ensure a good seal and reduce the likelihood of the lid sticking on. If you can't clean the lid properly, you can always store upside down.

The Velox Plus system does not contain silicon, and thus will not blotch other paint jobs in-flight.

How does this play out? Typically where you are using a silicon-based anti-foul it needs to be done last, so it doesn't blotch or foul your other jobs. In addition, you need to put up a screen to stop silicon getting across the boatyard. This then increases a risk of delay because you can't shuffle things around when you invariably need to.

By using Velox Plus you give your painting schedule more flexibility and resilience during the hull & metals anti-foul process.

Absolutely. For AIRLESS SPRAY: Apply one coat (180 microns wet). Recommended nozzle 0.12-0.18, max opening 30 degrees, pressure 100-180 PSI. Likewise, Metal Primer can be applied via Spray.

Unlike silicon, Velox Plus is a traditional antifoul that can be incorporated into your antifouling programme.

We assume this is a Year 1 application

- 1 thin layer of Boating Products Etch Primer

- 1 coat of Marlin Yacht Paints Metal Primer

- 3 coats of Marlin Yacht Paints Velox Plus

Typical Paint Schedule

- Day 1: Strip hull & all metals, then at end-of-day apply Etch Primer then Metal Primer

- Day 2: 3 x coats of Velox Plus

- Day 3: Apply hull anti-foul (Velox Plus is fine with a bit of overspray)

- Day 4: Launch

Notes

- Because this is Year 1, surfaces should be taken back to bare metal

- Apply with a roller, brush or spray

Surface preparation with a wax & grease remover, wiped thoroughly with clean rags

- Timings b/n Etch Primer & Metal Primer: between 30 min and 5 hours

- Timings b/n Metal Primer & Velox Plus coats: 2 hours minimum (at 30 degrees)

- Wait a minimum of 8 hours (at 30 degrees) before launching

Takeaways

- Remember Velox Plus works with ALL metals - including hanger plates, rudder stock & bearing housing, and trim tabs - not just the surfaces where silicon-based antifoul is applied

- If you are not pushed for time, ideally do a coat of Metal Primer / Velox Plus a day while you have your morning coffee

, and leave overnight to launch

- White allows for easy inspection and underwater scrub if needed, although it also comes in grey & black

Metal Primer guide to film thickness is it should be opaque when finished

- Metals & Oxidisation: apply primers within 6 hours, i.e. same day

Next year on haul out etch primer is not needed, metal primer touch up as required and then 3 x coats Velox Plus

It is not a problem. If you have used a silicon-based anti-foul there is a strong risk the metal substrate will be contaminated with silicon. To mitigate this we highly recommend using a thin coat of our Etch Primer on your initial application.

The Etch Primer will go a long way. We recommend you start with 100ml of Part A & 100ml or Part B. Always mix by volume.

Refer our blog post > Aluminium Powder Coatings and Epoxy Primer Finishes

Keying the surface of a prop will not change it's pitch. If done incorrectly it may eventually influence the profile but this too would take years.

With the Velox Plus system it is only every few years at most that the metal primer needs to be re-applied, involving taking the metal back to bare and re-keying to 80 grit.

Yes. We have excellent results with leg drives, duo-props, Inboard Propulsion System (IPS) propellers and any other high pressure propeller system where adhesion is an issue.

Also, refer our blog post > Aluminium Powder Coatings and Epoxy Primer Finishes

💡 take off that nice Apple watch in case of splatter

Refer our blog post > https://Preparing your Application

All depends on how well the paint system is adhering to the metal. Typically we see the system last 3 to 4 years. If the majority of paint is still on then all it needs is a spot prime with Metal Primer then 3 more coats of Velox Plus

Metal is porous, and this varies. Generally speaking make sure primer is applied within 6 hours, examples;

- Lead 2 hours

- Bronze 6 hours

- Stainless 24 hours

No, the manufacturer is quite adamant on this point "Never apply VELOX over any other type of antifouling"

This includes water-based primers. We have seen articles about this being done successfully, including Vyv Cox here https://coxeng.co.uk/stern-gear/propeller-antifouling-with-velox/ but even so be aware this in not in line with the manufacturer's recommendations.

Additionally, Marlin Yacht Paint's Metal Primer is recently improved. To quote them https://www.instagram.com/p/C4KeSoSIqwg/;

Metal Primer: the innovative new formulation for more effective protection against corrosion and better efficiency.

📌The METAL PRIMER is the result of a research and development project in collaboration with the University of Udine and state-of-the-art laboratories, resulting in improved product formulation with the addition of innovative adhesion promoters and galvanic current inhibitors.

Yes.

If you look at YouTube further down this page, you'll see Furio Benussi's Maxi 100 ARCA SGR. Arca SGR in a previous life won line honours in the 2003 Rolex Sydney Hobart as Skandia. The keel and appendages are finished with Velox Plus (in orange).

- Performance / Racing Finish -> Velox Plus is a hard vinyl, so you can spray apply to the hull and wet sand back to a high quality racing finish (320-600+ grit). This is not possible with an ablative equivalent.

- Durable -> Velox Plus is a hard vinyl, so it will not reduce film thickness through routine cleaning. An ablative equivalent will lose efficiency after approximately 4 months due to film thickness reduction.

- Weight Saving -> Because it does not contain copper it is substantially lighter than an anti-foul that does. Typically ablative equivalents will be cuprous oxide-based (powder added). As an example - assuming 600g/L of cuprous oxide in an ablative-equivalent - you would look to save 10-12kg on a TP52.

When looking for performance we suggest switching to a 2L pressure pot spray gun (rather than airless) for a smoother spray. There is no need to use thinners. Prepare your epoxy primer surface and then spray 5-6 coats of Velox Plus. In the end you will fair off 3 layers to get to your racing finish, leaving approx 2 layers intact.

If airless is your only option, drop tip size down to 12.

Please note Velox Plus is registered with the AVPMA in Australia & New Zealand for use as an antifoulant on underwater metals and running gear.

Exposure

Below are some photos of propellers and feet treated with Velox Plus and Metal Primer after at least 12 months at sea.

Velox Plus

Marlin Paints "Tens of thousands of boats successfully use Velox Plus, a rapidly growing number both in Italy and abroad thanks to the excellent results obtained"

ARCA SGR MAXI 100

Furio Benussi's Maxi 100 ARCA SGR won the 2021 12th edition of the 151 Miglia-Trofeo Cetilar, even if it failed to beat the record time set by Rambler88 in 2019.

Arca SGR in a previous life won line honours in the 2003 Rolex Sydney Hobart as Skandia.

The orange keel and appendages are finished with Velox Plus.

ARCA SGR MAXI 100

The 100-ft Italian Maxi ARCA SGR, the first yacht to round the Giraglia rock during the 68th edition Rolex Giraglia 2021.

Credit: https://www.sail-world.com/photo/319595

Read more about Arca SGR, competing in the 2021 Palermo-Montecarlo Race here on Sal Magazine.